In the same section

-

Share this page

Atmospheric plasma deposition of Crystalline inorganic coatings [Technology offer]

The technology in a nutshell

The invention of an induction heating system adapted to a reactor of the 'dielectricbarrier discharge' type known as DBD, opened up the field of crystalline deposits of inorganic material hitherto limited to deposition under vacuum or at very high temperature.

State of the art

Atmospheric plasmas have been used for a long time for ozone synthesis and for surface activation. Their main advantage is their ability to be run at atmospheric pressure, avoiding therefore the need of vacuum systems (chambers, pumps, transfer locks…).

When it comes to crystalline inorganic coatings, for years, the main option was to perform annealing on the quasi-amorphous deposited films.

The invention

The invention aims at providing a new and improved DBD plasma reactor for performing PECVD of a crystalline inorganic coating on a substrate.

Thanks to an original coupling of a substrate heating device based on an inductive current loop and located under the electrode and an atmospheric pressure dielectric barrier discharge, we show that one can deposit in one step crystalline vanadium oxide and titanium oxide, with grain sizes bigger than those achieved by post-deposition annealing in less time.

This original setup avoids electrical interferences with the high frequency plasma circuit, and allows fast heating of the substrate, located on top of a dielectric.

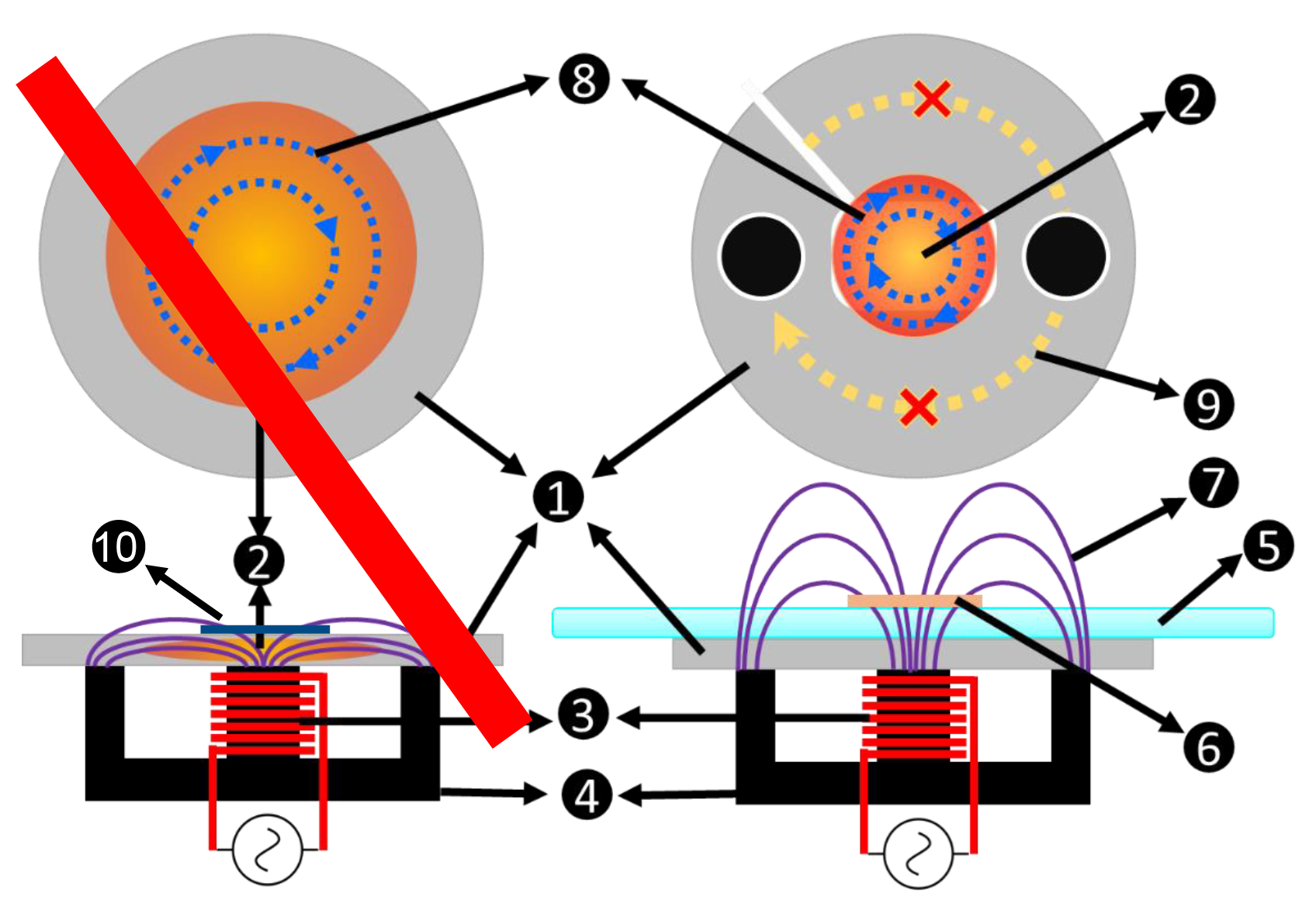

Fig. 1: configuration with non modified electrode (left) and with hollow electrode (right).

1) Electrode; 2) Heated zone; 3) inductioncoil; 4) ferrite core; 5) Dielectric; 6) Susceptor; 7) Magnetic field lines; 8) induced Eddy current (arbitrary direction); 9) impossible current line; 10) Substrate.

Key advantages of the technology

- Environmental friendly

- Allows to deposit coatings with unique properties

- Better control of the heating

- Avoids costly post-treatment annealing

- Energy efficient

Technology readiness level

Two prototypes of this new deposition system have already been produced. Actual developments focus on heating the system

to temperatures of at least 1000 ° C, in order to cover the crystallization temperatures of most of the deposits produced for

the microelectronics industry.

Potential applications

Vanadium oxides can be used for infrared sensors, as catalysts, as thermo chromic or electro chromic devices and as cathode for Li-ion batteries. Titanium oxide is well known as photocatalyst, where it has been shown that, in most conditions, the anatases are the most active ones.

The team

The Interface plasma laboratory of the faculty of Sciences of ULB is supervised by Professor François Reniers. The Chem Sin Team are focused on COLD ATMOSPHERIC PLASMAS and SURFACE TREATMENTS. The laboratory is equipped with plasma reactors (among them, 8 are atmospheric plasmas), an X photoelectron spectrometer with a monochromator (XPS), a FTIR spectrometer, DCA dynamic angle contact measurement system, an atmospheric mass spectrometer and an optical emission spectrometer.

The inventor

Professor François Reniers was born in Brussels in 1965. He defended a PhD in Chemistry at the Université Libre de Bruxelles in 1991 and was a post-doctoral fellow at the University of California at Berkeley. He was an invited professor at the Chinese University of Hong Kong in 2000.

Initially, his research activities are basic surface physico-chemistry, which he studied by Auger electron and photoelectrons X spectrometries. Since 1999, he oriented his team towards the developement of atmospheric plasmas for interfaces, in order to modify or deposit new layers. François Reniers has published 4 book chapters, more than 50 articles and is the inventor of 10 patents.

Relevant publication

- Improving the atmospheric plasma deposition of crystalline inorganic coatings, Remy A., Serigne Fall M., Segato T., Godet S., Delplancke-Ogletree M.P., Panini P., Geerts Y., Reniers F., Thin Solid Films, vol. 688, octobre 2019, p. 137437.

Keywords

- Atmospheric Plasma Technology

- Dielectric Barrier Discharge

- Crystalline inorganic coatings

Collaboration type

- Licence agreement

- R&D collaboration

IP status

- Pending application: EP19187406.4 - 19th July 2019

Inventors

- Pr François Reniers

- Dr Antoine Rémy

Contact

ULB Research Department

Arnaud Quintens

Business developer

+32 (0)2 650 96 78

arnaud.quintens@ulb.be