In the same section

-

Share this page

Coriolopsis gallica thermostable laccase [Technology offer]

The technology in a nutshell

The new method of thermoresistant laccases production using white-rot fungus Coriolopsis gallica.

State of the art

Laccases are a diverse group of multi-copper enzymes that oxidise a wide variety of organic and inorganic compounds. It is an economically important enzyme because of its ability to catalyze various oxidation reactions useful in industry.

Most laccases described in the literature were isolated from higher fungi, especially white-rot fungi belonging to the basidiomycetes. However, the extracellular level of the laccase enzyme produced by these fungi is low. Moreover, the high number of possible biotechnological applications of laccases, the thermostable and robust laccase of C. gallica in particular, and their potential uses in the environmental field necessitate industrial-scale production of active and stable laccase enzymes.

The invention

The inventors have introduced a new, thermostable laccase using an optimized method. The process involves submerged fermentation of a fungal strain called Coriolopsis gallica in a liquid fermentation medium within an agitated tank bioreactor. This allows for the production of high yields of laccase within a short period of time. As a result, the laccase produced is both robust against downstream processing and thermostable, with potential application in:

a) Agrofood;

b) Pharma;

c) Environment & Energy;

d) Materials & Engineering.

Lyophilized C. gallica laccase

- 2±0.5 U/mg activity

- Half-life: 20 min in 80°C

Key advantage of the technology

- Very high enzymatic resistance to heat

- Great stability over time during conservation, allowing to incorporate the technology into many industrial applications.

Potential application

- Bio-active molecule synthesis for pharma and agriculture

- Synthesis of bioactive natural products and their analogues

- Synthesis of antioxidant

- Water treatment

- Stabilization of food and beverage

- Lignocellulose pre-treatment

- Biosensors for detection of micropollutants

Technology readiness level

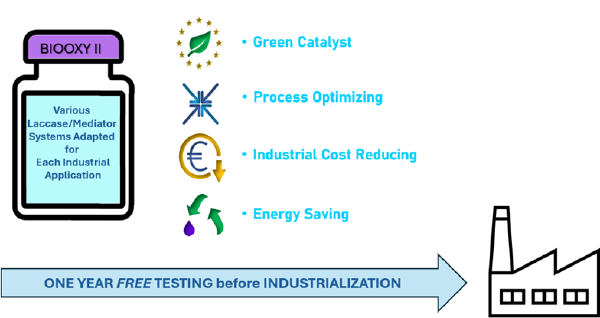

Special offer

The team

To modify some of these properties, genetic mutations are made after cloning of the laccase gene (s); the heterologous production of the protein makes it possible to study its modified function and / or structure.

The results of this research come from several disciplines: molecular biology, chemistry, computer science applied to microbiology (bacteria, yeast, fungi).

The inventors

Prof. Sigrid Flahaut (Head of team, Applied Microbiology Laboratory at EBB) is Associated professor in microbiology at ULB. She has worked on several fundamental or applied research topics using lactic acid bacteria, microbial biofilms or fungal enzymatic production.

Relevant publications

- High yield production in seven days of Coriolopsis gallica 1184 laccase at 50 L scale; enzyme purification and molecular characterization, Songulashvili et. al. Fungal Biology, April 2016.

- Production of a high level of laccase by submerged fermentation at 120-L scale of Cerrena unicolor C-139 grown on wheat bran, Songulashvili et. al. Comptes rendus Biologies, Feb 2015.

Keywords

- Laccase

- Enzyme

- Fermentation

- White-rot fungi

Collaboration type

- Licence agreement

- R&D collaboration

IP status

PCT patent ongoing

Inventors

- FLAHAUT Sigrid

- SONGULASHVILI George

Contact

ULB Research Department

Arnaud Quintens

Business developer

+32 (0)2 650 96 78

arnaud.quintens@ulb.be